Well Integrity

The NORSOK Standard D-010 defines Well Integrity as “the application of technical, operational and organizational solutions to reduce the risk of uncontrolled release of formation fluids throughout the life cycle of the well”.

This definition clearly outlines what Well Integrity is and where the solution is to be found. Well Integrity Platform (WIP) realizes that all three pillars; technology, operations and organization, should work together to achieve and advance well integrity. Hence, at WIP the education, research and development will focus on all the three pillars.

Our mission

Advance education, research & innovation for safe and economic production of oil, gas and geothermal energy.

A Well Integrity Platform (WIP) has been set up in cooperation with the Chair of Drilling and Completion Engineering (CDC) and also a leading well integrity expert, Prof. Kris Ravi.

WIP aims to bring together global operators, service providers, manufacturers, universities and technology providers with distinctive and complementary skills to contribute toward and benefit from the solutions developed. The strength of the platform lies in its independence and its ability to draw on the experience of personnel that have successfully worked in the industry to provide real-world solutions. WIP will have highly motivated professionals, students and staff drawn from across the globe.

WIP will consist of a globally connected network of members who need solutions for well integrity issues. With local and international partners (MUL chairs, international Universities, research organizations) it can offer unique solutions, services and answers to urgently needed and unsolved well integrity questions. The principal research tools that will be used are WIP Core Research, with results freely available to all members, and WIP Funded Projects, exclusively implemented for the benefit of an individual sponsor or for a member consortium in the form of a Joint Industry Project.

Department Petroleum Engineering in Leoben, Austria

Failure of Well Barriers

The goal of WIP is to identify challenges and provide practical solutions in the design and delivery of barrier elements to assure well integrity for the safe and economic production of energy.

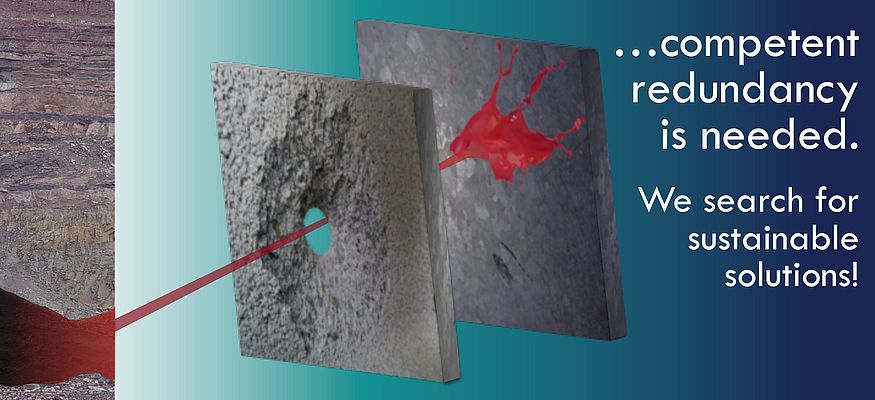

Cement sheath, packer, casing, tubular, threaded coupling, wellhead, safety valve and cap-rock are examples of barrier elements that provide integrity during well construction and production. It would be ideal if all barrier elements were intact during the life of the well so that energy can be produced safely and economically.

Failure of any one-barrier element may not compromise the whole integrity of the well immediately, but it can increase the risk in the long-term. However, failure of one barrier element could lead to a decrease in energy production, increase in water production, contaminate zones such as aquifers, diminish the economic outlook of the well and gradually corrode/degrade other barrier elements.

It is essential to understand the purpose and interdependence of each single barrier element and the concept of the barrier envelope. This will help in the effective design and delivery of safe wells and should also assist in reducing the overall cost at every step, including when any remedial work is needed and also during plug and abandonment.

Holistic view

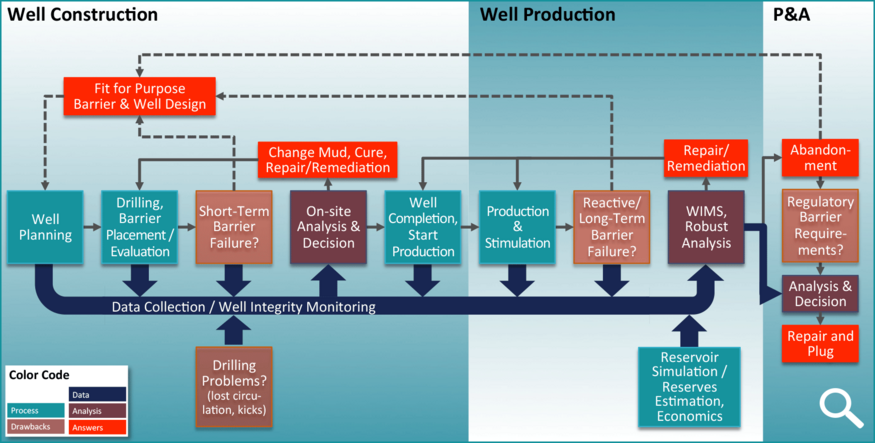

WIP will take a holistic view on well integrity over the complete life cycle of a well, as the requirements of the industry are multidimensional and differ from case to case.

With highly qualified expertise in different disciplines, WIP will focus its research on the entire life cycle of a well, from well planning and well construction, over production and stimulation until plugging and abandoning the well (P&A).

The objective is to reduce costs, improve efficiency, minimize wellbore downtimes and maximize profits. WIP will perform in-depth research on any well barrier element and on the nature of any short-term and long-term well integrity failures. WIP will collect and analyze “big data” from the entire life cycle of a well to assist in any critical well integrity management decisions in need of a more robust well integrity analysis. WIP will target old and new well installations, introducing fit for purpose barrier and well design concepts.

Large scale

A unique feature of WIP is to have access to MUL’s unique large scale testing facility close to Leoben, Zentrum am Berg (ZaB).

To be competitive from the beginning, WIP will focus on market niches, regional requirements, cost effective solutions and intelligent products such as real-time monitoring during the deployment of barrier elements, which could help in their successful delivery.

As technology advances, real-time monitoring of select downhole parameters during the life of the well could assist the industry to detect and prevent well integrity problems, avoid barrier failures and reduce remedial cost, increase energy recovery and safety as well as improve the economics of the asset.

Global network

WIP will be a tool providing access ot well integrity issues worldwide, initiating international academic cooperation and creating projects to help platform members around the globe define their specific needs.

Excellent international contacts have already been built up over the last few decades for example with the US, Brazil and with Russia. In this context, WIP will actively search for various international platform partners with unique and complimentary expertise and also set up WIP branches at dedicated locations.

For everybody

The results of WIP will be accessible to a large number of smaller stakeholders that at the moment are not able to participate in one of the rare existing well integrity R&D initiatives.

WIP shall assist stakeholders to receive unbiased information and helping them to conduct their business in a more effective way. WIP will be an attractive and unique offer for systematic international research providing a platform for knowledge exchange on well integrity. This will be accessible to a large number of smaller stakeholders who are not able to participate in one of the rare existing well integrity R&D initiatives and who do like to work in an independent environment with excellent training opportunities.

On what we build

The WIP team and members of the Chair of Drilling and Completion Engineering have been actively involved in research relating to well integrity for decades.

To create a holistic view, WIP will build on complementary expertise of key people in different subject areas such as well cementing, wellbore dynamics or drilling and production data analysis. The following list of publications is sorted chronologically; however, it represents just a selection of past team members’ activities and does not claim to be complete.

A. Elmgerbi, G. Thonhauser, M. Prohaska, A. Roohi, A. Nascimento: Application of Computer Programming to Estimate Volumetric Change of an Active Drilling Fluid System Cause by Elastic Deformation of an Open Borehole Section Wall, Global Journal of Computer Science and Technology, Volume, 16 Issue 3, Journal Article, Nov 2016

Milio C.C.M. Silva, Petrobras; Siva Rama Krishna Jandhyala, Sameer Bardapurkar, Venkata Gopala Rao Palla, Kris Ravi, Sheetal Singh, William Pearl, Halliburton: Measurement Procedures and Analysis of Fluid Invasion Drivers During Cement Hydration, OTC-26944, 2016, Offshore Technology Conference, Houston, Texas, USA, May 2-5, 2016

Urdaneta Javier, Ravi Krishna, And Pacheco Jaime, Halliburton; Jaramillo Oscar And Patiño John, Emerald: Low Solids Shear Dependent Fluid System to Plug Zones for Preventing Fluid Influx and Loss, IADC/SPE-178771, 2016, IADC/SPE Drilling Conference and Exhibition, Fort Worth, Texas, USA, March 1-3 2016

Asad Elmgerbi, Gerhard Thonhauser, Michael Prohaska, Abbas Roohi And Andreas Nascimento: General Analytical Solution for Estimating the Elastic Deformation of an Open Borehole Wall, ISSN 2229-5518, International Journal of Scientific & Engineering Research, Volume 7, Issue 1, Journal Article, Jan 2016

Jandhyala, S. R. K., Halliburton, Ravi, K., Halliburton, Anjos, J., Petrobras: Design Procedure for Cementing Intercalated Salt Zones, OTC-26310, Offshore Technology Conference, OTC Brazil, Rio de Janeiro, Brazil, October 27-29, 2015

Aiex, Cristina, Petrobras, Campos, Gilson, Petrobras, Deshpande, Abhimanyu, Halliburton, Chiney, Abhinandan, Halliburton, Patil, Sandip, Halliburton, Ravi, Kris, Halliburton: An Experimental Study on Effects of Static CO2 on Cement Under High-pressure/High-temperature Conditions, OTC 25659, Offshore Technology Conference, Houston, Texas, USA, May 4-7, 2015

Ashena, R. & Thonhauser, G.: Application of Artificial Neural Networks in Geoscience and Petroleum Industry, ISBN 978-3-319-16530-1, Artificial Intelligent Approaches in Petroleum Geosciences. NY: Springer, S. 127 166 S, Book Chapter, 2015

Arnaout, A., O'Leary, P., Esmael, B. & Thonhauser, G.: Distributed Recognition System for Drilling Events Detection and Classification, , International Journal of Hybrid Intelligent Systems, Vol 11, Journal Article, 2014

Arnaout, A., Esmael, B., Fruhwirth, R. & Thonhauser, G.: Drilling Events Detection Using Hybrid Intelligent Segmentation Algorithm, Hybrid Intelligent Systems (HIS) Conference, Journal Article, 2013

Prohaska, M. & Thonhauser, G.: Environmental (Baseline) Monitoring for Shale Gas Development in Ukraine, USAID, Report, 2012

M. Prohaska: The Importance of Wellbore Integrity for Shale Gas Well Constructions, Conference Paper, Shale Gas Conference – The Changing Landscape of Energy Security and Environmental Stewardship, Cape Town, SA, October 2012

Prohaska, M. & Thonhauser, G.: Environmental and Regulatory Assessment: Ukraine Shale Gas, USAID, Report, 2012

Andre Garnier, Jean Benoit Laudet, Sandip Patil, Rahul Patil, Kris Ravi, Luis Ferreira: Effect of Acid Gas on Cement Sheath Integrity: Experimental Findings, SPE-SAS-401, SPE Saudi Arabia Section Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, Apr 8-11, 2012

Repetto, C; Moroni, N; Pilia, L; D'Ancona, E; Ravi, K; Santra, A: Successful Application of Acid-soluble Plugs in Openhole Slotted-liner Completion, SPE-129159, SPE Oil & Gas India Conference [OGIC], Mumbai, India, Jan 20-22, 2010

Moroni, N; Santra, A; Ravi, K; Hunter, W: Holistic Design of Cement Systems to Survive CO2 Environment, SPE-124733, Annual SPE Technical Conference, New Orleans, LA, Oct 4-7, 2009

Moroni, N; Ravi, K; Hemphill, T; Sairam, P: Pipe Rotation Improves Hole Cleaning and Cement-slurry Placement: Mathematical Modeling and Field Validation, SPE-124726, SPE Offshore Europe Oil and Gas Conference, Aberdeen, UK, Sep 8-11, 2009

Ravi, K; Iverson, B; Moore, S: Cement-slurry Design to Prevent Destabilization of Hydrates in Deepwater Environment, SPE-113631, SPE Drilling & Completion v.24, no.3, pp.373-377, Journal Article, Sept 2009

Reddy, B R; Xu, Y; Ravi, K; Gray, D; Pattillo, P D: Cement-shrinkage Measurement in Oilwell Cementing – A Comparative Study of Laboratory Methods and Procedures, SPE-103610, SPE Drilling & Completion v.24, no.1, pp.104-114, March 2009, Journal Article, March 2009

Moroni, N; Repetto, C; Dettori, N; Ravi, K: Zonal Isolation Achieved in Kashagan Field Through Integrated Approach, SPE/IADC-119296, SPE/IADC DRILLING CONFERENCE, Amsterdam, The Netherlands, March 17-19, 2009

Ravi, K; Fukuzawa, M; Hunter, W J; Noerdin, A I: Advanced Cement Systems Used to Improve Geothermal Well Reliability in Java, SPE-115638, Annual Spe Technical Conference [ATCE 2008], Denver, CO, Sep 21-24, 2008

Ravi, K; Mcmechan, D E; Reddy, B R; Crook, R: A Comparative Study of Mechanical Properties of Density-reduced Cement Compositions, SPE-90068, SPE Drilling & Completion v.22, no.2, pp.119-126, June 2007, Journal Article, June 2007

Savery, M; Reddy, B R; Ravi, K; Whitfill, D; Aston, M: Deciding on Optimum Solution for Loss Circulation Challenges, 53rd Annual Southwestern Petroleum Short Course Meeting, Lubbock, TX, Apr 26-27, 2006

Ravi, K; Mcmechan, D E; Reddy, B R; Crook, R: A Comparative Study of Mechanical Properties of Density-reduced Cement Compositions, SPE-90068, Annual SPE Tech. Conference, Houston, TX, Sep 26-29, 2004

Griffith, J E; Lende, G; Ravi, K; Saasen, A; Nodland, N E; Jordal, O H: Foam Cement Engineering and Implementation for Cement Sheath Integrity at High Temperature and High Pressure, SPE-87194, IADC/SPE Drilling Conference, Dallas, TX, Mar 2-4, 2004

Ravi, K; Bosma, M: Cement Sheath Design for Deepwater Applications, 7th Annual Pennwell Offshore West Africa Conference, Windhoek, Namibia, Mar 11-13, 2003

Heathman, J; Tare, U; Ravi, K: Understanding Formation (In)stability During Cementing, SPE/IADC-79913, SPE/IADC Drilling Conference, Amsterdam, Netherlands, Feb 19-21, 2003

Ravi, K; Bosma, M; Gastebled, O: Improve the Economics of Oil and Gas Wells by Reducing the Risk of Cement Failure, SPE-74497, IADC/SPE Drilling Conference, Dallas, Texas, Feb 26-28, 2002

Biezen, E; Van Der Werff, N; Ravi, K: Experimental and Numerical Study of Drilling Fluid Removal From a Horizontal Wellbore, SPE-62887, Annual SPE Tech. Conference, Dallas, Texas, Oct 1-4, 2000

Bosma, M; Ravi, K; Van Driel, W; Schreppers, G J: Sealant Selection for the Life of the Well, SPE-56536, J. Petrol. Technol. v.52, no.7, pp.51-52, July 2000, Journal Article, July 2000

Ravi, K; Biezen, E N; Lightford, S C; Hibbert, A; Greaves, C: Deepwater Cementing Challenges, SPE-56534, Annual SPE Tech. Conference., Houston, TX, Oct 3-6, 1999

Bosma, M; Ravi, K; Van Driel, W; Schreppers, G J: Design Approach to Sealant Selection for the Life of the Well, SPE-56536, Annual SPE Tech. Conference, Houston, TX, Oct 3-6, 1999

Michael Prohaska, Mining U. Leoben; Rudolf Fruhwirth, Joanneum Research Leoben; M.J. Economides, Texas A&M U: Modeling Early-time Gas Migration Through Cement Slurries, SPE Drilling & Completion, Volume 10, Number 3, Journal Article, September 1995

Griffith, J E; Ravi, K M: Monitoring Circulatable Hole With Real-time Correction: Case Histories, SPE-29470, SPE Prod. Oper. Symp., Oklahoma City, OK, Apr 2-4, 1995

Prohaska, Michael, Mining U. Leoben; Ogbe, D.O., U. Of Alaska Fairbanks; Economides, M.J., Mining U. Leoben: Determining Wellbore Pressures in Cement Slurry Columns, SPE 26070-MS, SPE Western Regional Meeting, Anchorage, Alaska, 26-28 May 1993

Sutton, D L; Ravi, K M: New Method for Determining Downhole Properties That Affect Gas Migration and Annular Sealing, SPE-19520, 64th Annual SPE Tech. Conference, SAN ANTONIO, TX, Oct 8-11, 1989